CNC Machining for Rapid Prototyping: Bringing Ideas to Life Faster

New product development is always an exciting and daunting process. Getting that design just right, getting prototypes for testing and design improvements, then moving to full production, all takes a long time and a lot of effort. Rapid prototyping is necessary for speeding up the development of new products. Making a prototype as quickly as possible helps move the process along through testing, and helps push the prototype to production, and eventually gets the product to the market that much faster.

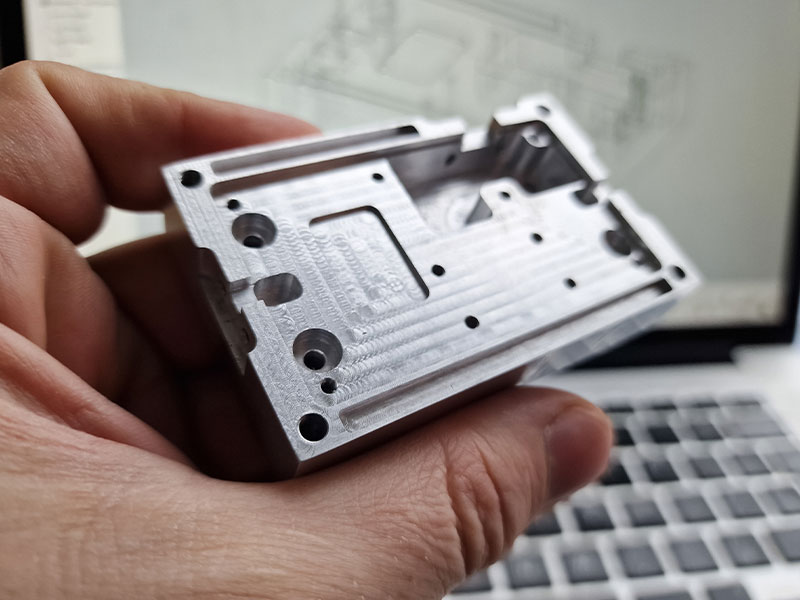

There are many different options of manufacturing techniques to choose from when it comes to actually getting a prototype made. One of the common ways prototypes are manufactured is through CNC machining, as it’s a fast and accurate way to make a brand new prototype that will offer an accurate picture of how the final product will function. We would know–rapid prototyping is one of the services that we offer here at Trimen Industrial!

Why choose CNC Machining for Rapid Prorotyping

CNC machining has a number of benefits when it comes to any type of production, large or small, prototype or full product. However, it offers a number of advantages for rapid prototyping needs that other manufacturing methods can’t offer. For one, any prototype made through CNC machining will offer the most accurate portrayal of how the final product will look and function, since machining offers much better dimensional accuracy and stability than other techniques. This is especially helpful for prototype testing–with a CNC machined part, the tests will offer much more accurate results on how the actual product will function.

It also provides an idea of what to expect during full production, like potential problems that might arise while trying to make the part, and allows manufacturers to then plan ahead as the product moves into the full production phase. Every project is different, and there are always going to be little snags and surprises–but by using CNC machining to make the prototype, you’ll have much more insight into what to expect and how to prevent any potential issues.

That also leads us to another advantage of CNC machined prototypes–it can not only improve the speed of the prototyping phase, but it can also improve the efficiency of the rest of product development too. The more insight you can get from the prototype, the more prepared you’ll be for the subsequent steps of the product’s development–and the faster you’ll be able to get your product to the market!

Looking for a supplier of precision machining for your rapid prototyping needs?

Trimen Industrial LLC is an expert in precision CNC machining, and we serve a wide range of customer needs in applications, production volumes, and more! Head over to our website to learn more about what we can do for you and request a quote today!