Swiss vs. Lathe Turning: The Difference between Swiss and Conventional CNC Lathes

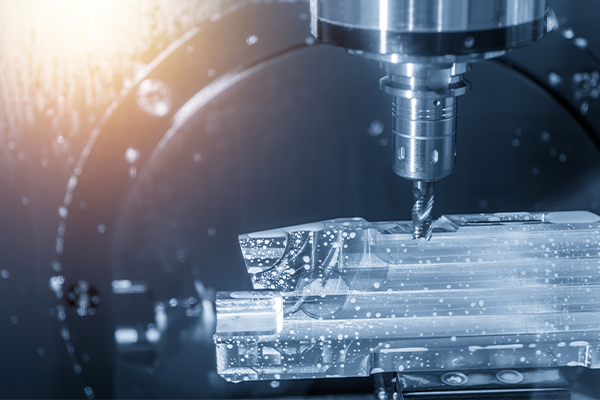

Swiss turning and conventional CNC turning are very similar operations–and both function relatively the same way. Each machine holds a spinning workpiece while different precision cutting tools are moved into position around it, carefully removing material to achieve the desired shape. However, these two types of lathe turning are actually very different, and often are used for different projects and applications.

Different Designs

The difference between these two types of lathe turning stems from the configurations of each type of machine. The conventional CNC lathe holds the workpiece at one or both ends, without any other support, while the tools are moved around it. However, in a swiss turning center, the workpiece is fed through a guide bushing, and the actual machining is always done near the point where the workpiece is best supported. This offers a number of advantages over conventional turning, as it ensures that much less mechanical stress is introduced to the workpiece during the operation.

Different Applications

Swiss turning and conventional CNC turning might perform similar machining operations, but their different ways of handling the workpiece make each type of lathe better suited to different types of manufacturing projects.

Swiss CNC turning typically operates on multiple axes and provides much more support for the workpiece, which allows them to make parts with extremely tight tolerances, even if they’re very, very small. They’re best for tight tolerance projects and smaller components, especially ones that have delicate features or complex designs. Industries like Medical device manufacturing, Aerospace components, electronics, and automotive manufacturing benefit from the extremely tight precision of Swiss lathe turning.

However, Swiss machining tends to fall short when it comes to larger parts or extremely hard materials. Traditional CNC turning, while not able to provide the level of accuracy that a Swiss lathe offers, is still an incredibly precise method of manufacturing compared to manual methods, and offers lower production costs and shorter turnaround times. Conventional CNC turning is best suited for relatively larger components and high-volume production, and is extremely versatile in the tooling and operations that it offers.

Looking for an expert in both Swiss turning and conventional CNC turning services?

Trimen Industrial LLC offers a comprehensive range of high-precision CNC turning services, and serves a variety of industries with our expertise. Head over to our website to request a quote for your next manufacturing project from us!