Understanding CNC Machining: A Guide to this Critical Innovation in Precision Manufacturing

CNC Machining services have become one of the most widely used manufacturing services, and often one of the go-to services for the production of precision plastic and metal components. This type of manufacturing is used to make a wide range of production volumes of three-dimensional parts, through an almost entirely automated and computer-controlled machine.

What is CNC Machining?

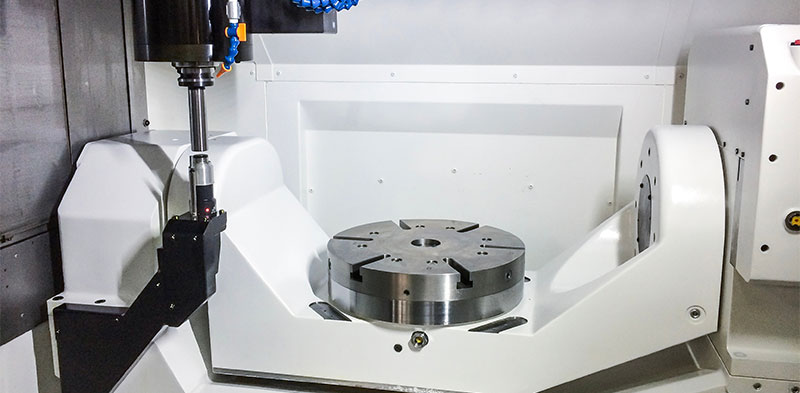

Computer numerical control machining, or CNC machining, is a manufacturing process where the tooling in a machine is guided entirely by pre-programmed computer software to create the designed shape and features of a part. The software converts a CAD file into instructions that guide the tool through repetitive cycles, all with very little involvement from operators.

The Types of CNC Machining Services

CNC machining comes in a wide range of forms thanks to the ease with which computer numerical control can be integrated into various manufacturing processes. Today, nearly every large scale production CNC manufacturing technique is partially or fully automated for ease of use and improved efficiency.

Milling is one of the oldest and most common types of CNC machining, in which a rotating tool removes material from a workpiece in order to achieve the desired shape. CNC mills can operate on multiple axes, with the most sophisticated working on 5 or more with multiple different tools.

Turning is another common type of CNC machining, where a tool operates on a rotating workpiece in order to get the desired shape. It’s primarily used for cylindrical parts or parts that are symmetrical along their axis.

CNC milling and turning are the best examples of CNC machining and some of the most common types as well, but there are many other CNC machining and manufacturing methods out there.

Revolutionizing Manufacturing

CNC machining services have had a major impact on the manufacturing industry. They give manufacturers the ability to create parts with far more precision and much more consistent quality than was possible before the development of computer numerical control. They are also an incredibly efficient way to produce large volumes of complicated parts, reducing lead times and overall costs. Plus, with the use of computer numerical control, there is little to no room for human error, especially across large batches of parts. The CNC machine can make parts repeatedly with little need for downtime for adjustments.

Looking for a supplier of CNC machining services?

Trimen Industrial, LLC goes above and beyond for our customers, providing tight tolerance CNC machining, in-house painting and powder coating, and a variety of other services. Head over to our website to learn more about what we can do for you!